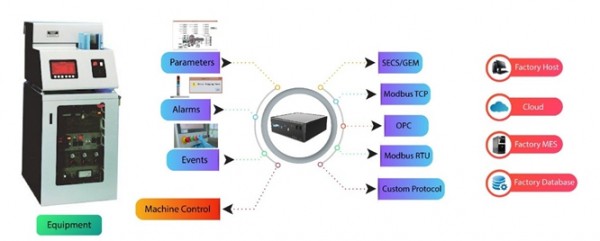

SECS/GEM for Old/Legacy Equipment

Enabling SECS/GEM capability on your EXISTING EQUIPMENT

Does your factory have equipment which you can’t get SECS/GEM capability or it’s just too expensive?

Are you an Equipment Manufacturer who wants to offer SECS/GEM capability without modifying existing software or hardware?

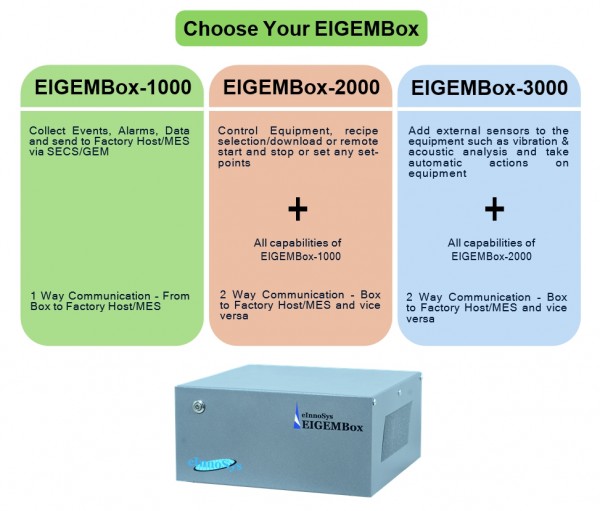

EIGEMBox solves these problems!!

And it does without requiring any software or hardware installation on your equipment!

EIGEMBox-2000 is a unique product that enables SECS/GEM, Modbus or OPC capability on your existing equipment, and it does it without requiring any software or hardware installation on the equipment. All you need is to connect the display cable (VGA, DVI or HDMI) from your equipment’s PC to EIGEMBox. If you want to control the equipment for recipe selection/download or remote start and stop or setting any set-points, you need to connect EIGEMBox to the equipment PC through keyboard and mouse ports (USB or PS/2) as well. That’s it!

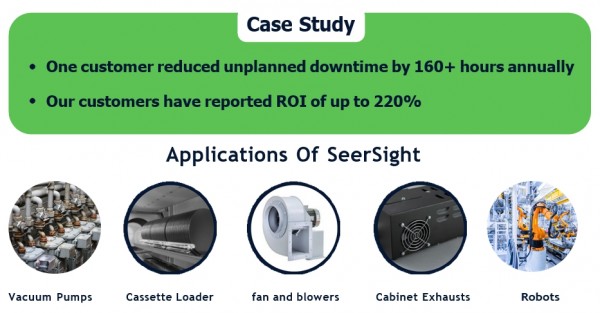

• SeerSight

continuously monitors your equipment's health and status.

ØImprove Yield & Product Quality

ØReduce Unscheduled Equipment

Downtime

ØSave Maintenance Cost

ØProactively moitor the health of critical devices

& Much more.

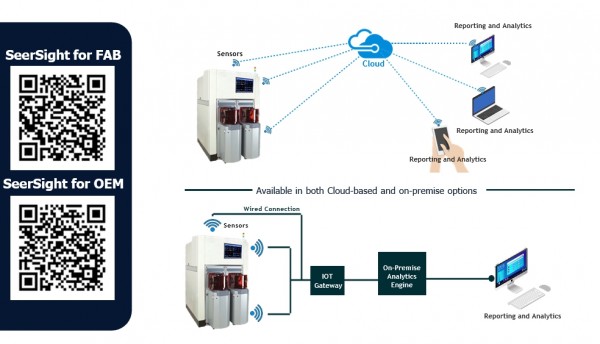

SeerSight

AI/ML based Predictive Maintenance System

SeerSight continuously monitors your equipment's health and status. Upon detecting anomalies in your equipment, SeerSight predicts and quickly alerts your Equipment Engineers & Managers, days in advance, so that maintenance can be scheduled at your convenience, increasing manufacturing uptime, preventing scrapping of expensive wafers and wastage of components that do not require replacement yet.

Benefits Of SeerSight

• Improve Yield & Product Quality

• Reduce Unscheduled Equipment Downtime

• Save maintenance cost

• Proactively monitor the health of critical devices & much more….

Features of SeerSight

Fixing something before it breaks is more efficient and cost-effective than fixing it after it breaks

SeerSight comes with all required sensors, hardware and AI/ML based software

E-mail : sales@einnosys.com | Call : +1.805.334.0710 | Skype & WeChat : einnosys